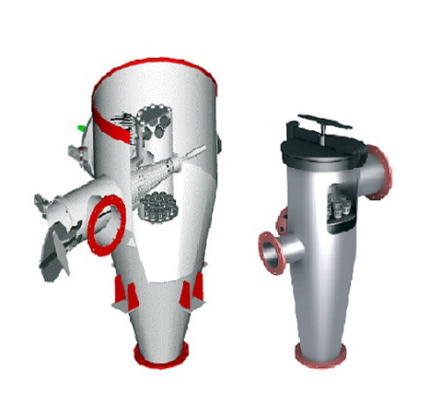

EE WATER JET VACUUM SYSTEM

EE water jet vacuum system can create vacuum upto 720 mm Hg abs. (40 Torr) in lowest generation time depends on water temperature & water quality.

Description

Water Jet Vacuum System absorbs vapors during co-current mixing with water droplets. Non Condensable gases are evacuated by water jets without the need of any extra device or equipment like vacuum pumps, steam boosters or steam ejector.

Spray nozzles primarily condense water vapors and then increase momentum of water flow in the tailpipe. As it moves rapidly down the tail pipe, multi-phase flow of heated water and air bubbles is compressed. Effective use of cold water and residual heat of vapors, make this combination most energy efficient system.

Working

Features

- System can create vacuum upto 720 mm Hg abs. (40 Torr) depends on water temperature & water quality.

- Lowest Vacuum generation time.

- Design in such a manner so that it can run with water pressure between 0.4 to 0.6 bar g cold water pressure at condenser platform.

- Compact Design.

- Hinge type Man Hole ease the maintenance.

Advantages

- Water Inlet pressure requirement is very less (0.4-0.6 bar g)

- Efficient design makes it low Water Consumer.

- Due to low flow & pressure requirement, power consumption is less.

- No moving part; maintenance free.

- Operation cost is comparatively very less.

- Rough & Tough; can work upto 2500 TDS level.

- Low Installation period – Max. 8 to 10 hrs.

Disadvantages

- EE Water Jet Vacuum system cannot use for more than 720 mm HG vacuum system due to water inlet temperature limitation, if clean water is there.

- The system is not suitable for NCG / Air evacuation ONLY.

- EE Water Jet Vacuum system works on direct contact of water with vapor / NCG. Thus cannot be used where vapors are product or cannot be mixed with water due to pollution norms.

- Height limitation; system has to install at a height of 12 meter; structure cost will be there if not exist already.

COMPARISON- 1 STEAM JET EJECTOR WITH VACUUM PUMP VS EE WATER JET VACUUM SYSTEM

| Steam Jet Ejector with Vacuum Pump | EE Water Jet Vacuum Pump |

|

|

COMPARISON- 2 BAROMETRIC CONDENSER WITH VACUUM PUMP VS EE WATER JET VACUUM SYSTEM

| Barometric Condenser with Vacuum Pump | EE Water Jet Vacuum System |

|

|

Applications

- Multi Effect Evaporators

- Spray Dryer

- Bleaching – Batch & Continuous

- Auto Clave / Hydrogenation

- Cookers / Batch Evaporators

- Moisture Removal Application

Many others…