HEAT PIPE- WASTE HEAT RECOVERY SYSTEM

Heat Pipe is a thermal energy absorbing and transferring tool which can transfer heat at the sonic speed to the other end and hence it is also known as the super conductor of heat transfer.

Description

Heat Pipe is a thermal energy absorbing and transferring tool which can transfer heat at the sonic speed to the other end and hence it is also known as the super conductor of heat transfer.

The heat pipe can carry about one thousand times more heat energy than all equivalent size of Copper rod for the same temperature gradient. In other words it has an effective thermal conductivity several hundred times more than an equivalent size of copper.

WORKING / CONSTRUCTION

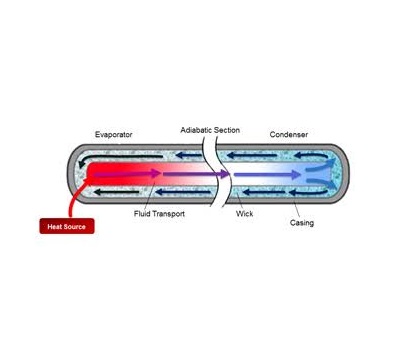

- The heat pipe is a evacuated tube made out of Stainless Steel, Copper, Aluminum.

- The pipe is evacuated up to 10-4 Torr and is filled with small quantity of liquid like Water, Ethanol, Methanol etc.

- When installed vertically the lower portion is called as the evaporator section and the upper portion is called as the condenser section.

- When the evaporation section comes in contact with the hot fluid, the liquid inside heat tube vaporizes even at very low temperature because of the vacuum. The vapors go to the condenser section and transfer heat to the outside of the pipe which heats up fluid in contact.

Features

- The heat exchanger is provided with bolted insulated panels which can be removed for the cleaning of the external surface of the heat pipe. Internal cleaning of the pipes is not required as the pipe is sealed from both the ends.

- All the heat pipes are screwed to the main tube sheet, and hence can be easily removed for cleaning of the sticky deposition of the particulate matter content in the flue gas. Because of this screw type construction it is easy to replace one single pipe in case a single pipe is to be replaced.

- The heat recovery system is installed in bye pass mode to the main ducts and can be easily bye-passed for maintenance without taking the shut down.

- The dampers can be made motorized if required.

- All our heat exchangers are equipped with the HMI control panel which gives the energy recovery at the hot as well as the cold side of the heat recovery.

Comparison – Heat Pipe

| FACTORS | HEAT PIPE | SHELL & TUBE | PHE |

| Heat Transfer | Very high | Low | Low |

| Heating Media | Vapour | Conduction | Conduction |

| M.O.C | S.S/Cu/Al | SS/Cu/MS | SS |

| Recoverable Heat | 50 – 500°C | 100 – 500°C | 100 – 500°C |

| Size | Compact | Large | Compact |

| Maintenance | Low | Very High | Very High |

| Maintenance Time | 20 -30 Minutes | 1-2 Days | 8-10 Hrs. |

| Payback | 12-15 Months | >24 Months | >24 Months |

| Installation | Offline | Online | Online |

| Average Life | 10+ Years | 5+ Years | 2+Years |

| Size | Compact | Large | Compact |

| Maintenance Time | 20 -30 Minutes | 1-2 Days | 8-10 Hrs. |

| AIR-AIR HEAT PIPE HEAT EXCHANGER | AIR-LIQUID HEAT PIPE HEAT EXCHANGER |

|

|