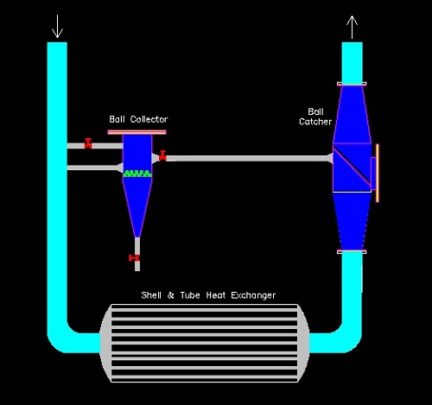

EE ONLINE CLEANING SYSTEM

The online cleaning system consist basically two parts; Ball Collector & Ball Catcher. The system will be installed as per below diagram. The cooling water will be introduced in Ball Collector chamber while opening the automatic valve. The balls will get out from the exit to the cooling water line which enters into heat exchanger tubes and wipe out the dirt inside. The dirty balls will be collected at catcher which further received at Ball Collector.

The drain valve will opened to rinse the ball gently. The cycle repeats in the same way again. Automation system will control the cleaning as well showing the health of condenser.

Description

The Cooling capacity of the majority of medium to large central air conditioning systems are designed around a re-circulating open water cooling system. Water flow in the tubes of Shell & Tube heat exchanger and remove the heat from the coolant gas.

Water contains low solubility salts and sediments that deposit and build a stony scale on the inner tubes surfaces, causing fouling of the heat exchanger unit. Fouling of the heat exchanger unit is causing reduction of the Air Conditioning C.O.P. For example ·1mm of scale can be deposited in 2000 hours of operation which reduces the system efficiency by 45%. Usually scale, fouling sediments can be found after 100-200 operation hours depending upon the water quality. This may results to add more capacity per unit, add units as backup during disassembly and cleaning which finally raise the electricity bills.

WHY CLEANING ?

- Low solubility salts in cooling water develop scales in condenser tubes.

- Scaling in tubes reduce the cooling of refrigerant.

- Improper cooling of refrigerant increases duty cycle of chiller.

- More duty cycle means more power requirement.

CONVENTIONAL METHODS OF CLEANING

Water Jet Cleaning

- Laborious & Time consuming.

- Need backup for cooling.

- Water wastages.

- Chances of accidents.

Chemical Cleaning

- Chemical cleaning needs acids which is having certain cost.

- Environmental problems due to the disposal of the chemicals.

- Laborious & Time consuming.

- Need backup for cooling.

- Chances of accidents.

- Shortening the life of heat exchanger.

FEATURES

- 100% reliable system.

- User defined cleaning cycle.

- The soft balls made of natural rubber with special wear resistance. It is economical and normal life cycle of 3-4 months depending upon the type & mass of dirt.

- It is fully automatic to maintain the health of condenser.

ADVANTAGES

- It is a simple & reliable hydro-mechanical online cleaning system.

- It keeps heat exchanger’s tubes permanently and absolutely clean.

- It is simple to install and requires no modification to the heat exchanger.

- The ball flow does not disturb the condenser water flow.

- It does not impair environmental quality.

- It preserves heat exchanger’s C.O.P. as designed by the manufacturer

- Reduce maintenance and chemicals cost.

- The payback period is not more than 2 years. Usually not crossing 1 year.

- It prevents chiller’s compressor wear & tear due to excessive load to maintain the same cooling.

APPLICATION

- HVAC

- Industrial Chiller

- Surface Condensers

- Evaporators