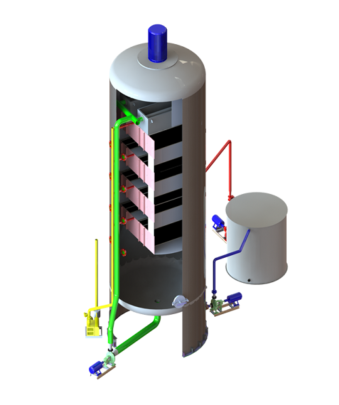

EE MVR EVAPORATOR

MVR Evaporators are widely used in many applications, including Industrial wastewater treatment, Chemical industry & Food industry etc.

Description

It is a specially designed Plate Type Evaporator using Mechanical Vapor Re-compressor for compressing the vapor generated from the evaporation and reuse those vapor for further heating the product. Thus heat is required in initial stage or may be negligible quantity for temperature correction.

Plate packs will be welded type having cavities of approximately 10-12 mm; thus maintenance free and having very high heating surface in very compact space.

Features

- No heat is required at all if the feed temperature is >65°C.

- Heat is required while start or negligible amount for temp. correction.

- Power requirement will be in the range of 10-12 kW/Ton of evaporation.

- It can work on very low temperature difference (ΔT).

- Heating will be done at low temperature (50-60 °C). So probability of corrosion and scaling due to various salts will be negligible.

- No cooling water required.

- Fully Automatic to produce consistent product concentration.

MVR EVAPORATOR – COMPARISON

| FACTORS | MVR-EVAPORATOR | MEE |

| Steam Requirement | Negligible (if feed temp.>65°C) | Very High |

| Power Requirement | 10-12 kW/Ton | 5-6 Times |

| Fouling | Lowest | High |

| Recoverable Heat | 50 – 60°C | >120°C |

| Space Requirement | Very Less | Large |

| Maintenance | Low | Very High |

| Installation Time | Plug & Play Type | Very High |

| Average Life | 10+ Years | 5+ Years |

| Payback | 1-2 Years | High |

| Recoverable Heat | 50 – 60°C | >120°C |

| Space Requirement | Very Less | Large |

| Plant Start up Time | Very Low | Very High |

| CONVENTIONAL MULTI EFFECT EVAPORATOR (MEE) | MVR BASED EVAPORATION SCHEME |

|

|

| CONVENTIONAL EFFLUENT TREATMENT PLANT (ETP) | MVR BASEDEFFLUENT TREATMENT PLANT (ETP) |

|

|

Results