ENERGY AUDIT

In any industry, the three top operating expenses are often found to be energy (both electrical and thermal), labour and materials. If one were to relate to the manageability of the cost or potential cost savings in each of the above components, energy would invariably emerge as a top ranker, and thus energy management function constitutes a strategic area for cost reduction. Energy Audit will help to understand more about the ways energy and fuel are used in any industry, and help in identifying the areas where waste can occur and where scope for improvement exists.

- Steam Distribution & Consumption Study

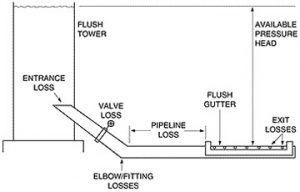

- Water Distribution & Energy Losses Study

- Vapor Bleeding Study

- Vacuum System Study

Steam is a principle utility used for heating and vacuum creation. The steam pipe line design shall be such that there shall not be any considerable loss but unfortunately it is not happening. The pipe lines are over burden as the plant getting older; thus losses start. The steam consumption is getting high.

CEPL measures the steam parameters and analysis the data to reduce / eliminate the energy losses with recommended measures.

CEPL strictly do not believe in recommendation but in proving the recommendation. Thus we offer our product / solution with payback period.

The water pipe line design shall be such that there shall not be any considerable loss but unfortunately it is not happening. The pipe lines are over burden or under size design as the plant getting older; thus losses start. The pump starts consuming more power to avail the same input at consumer end.

CEPL measures the water pump parameters and analysis the data to reduce / eliminate the energy losses with recommended measures.

CEPL strictly do not believe in recommendation but in proving the recommendation. Thus we offer our product / solution with payback period.

Energy Engineering understands the value of waste heat. There are many source of waste heat in the plant like condensate, blow off steam, residual vapor going in condenser etc. The study is required to understand the use of this heat.

CEPL finds the source of waste heat, measures the quality and magnitude of heat, analysis the utilization of that heat in existing / modified process.

CEPL strictly do not believe in recommendation but in proving the recommendation. Thus we offer our product / solution with payback period.

Vacuum need to boil / evaporate unwanted liquid like water / moisture / fatty acid at below than atmospheric pressure. It helps to prevent burning, coloring, false graining etc. Vacuum required to reduce the evaporation time and helps in degassing to avoid bacteria growth in process.

CEPL understands the vacuum system and finds the leakages of vacuum in existing / modified process.

CEPL strictly do not believe in recommendation but in proving the recommendation. Thus we offer our product / solution with payback period.